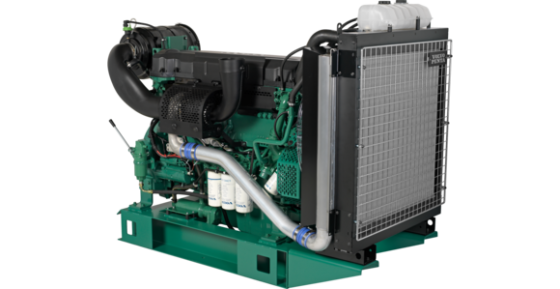

Model Numbers: 708 – 1H – 00260 (also referred to as 7081H00260)

Applicable Equipment: Komatsu Bulldozer D375 and D375A – 6

Function: As a hydraulic pump, it is a critical component of the bulldozer's hydraulic system. It supplies the necessary hydraulic power to operate various functions such as blade lifting, angle adjustment, and track drive motors.

2. Spécifications de performance

2.1 Débit

Rated Flow: The rated flow rate of this hydraulic pump is a crucial parameter that determines the speed of hydraulic operations. It is typically [X] litres par minute (L/min). This value may vary depending on the rotational speed of the pump and the specific operating conditions. The rated flow rate directly impacts the speed at which the bulldozer's hydraulic actuators can move.

Variable Flow Capability: The pump may have a variable flow control mechanism. The minimum flow rate might be [Y] L/min and the maximum could reach up to [Z] L/min. This variability allows the operator to adjust the speed and power of the hydraulic functions according to the work requirements. Par exemple, a lower flow rate can be used for precise blade adjustments, while a higher flow rate is needed for more force – intensive operations like pushing heavy loads.

2.2 Notes de pression

Pression nominale: The rated working pressure of the pump is [P1] mégapascals (MPA). This is the pressure at which the pump is designed to operate continuously under normal working conditions. It ensures the efficient transfer of hydraulic energy to the bulldozer's hydraulic components such as cylinders and motors.

Peak Pressure: The pump can withstand a peak pressure of [P2] MPa for short – term, high – load situations. Cependant, continuous operation at or near the peak pressure may lead to reduced service life and potential damage to the pump and other hydraulic system components.

3. Construction and Components

3.1 Type de pompe

Pompe à piston: Le 708 – 1H – 00260 pump is typically a piston – pompe de type. Piston pumps are known for their high – efficiency and ability to generate high pressures. Les pistons se déplacent dans un mouvement alternatif à l'intérieur des cylindres pour attirer et décharger le liquide hydraulique.

Bloc-cylindres: The cylinder block is a vital component made of high – strength, wear – resistant materials such as alloy steel. It provides the housing for the pistons and is precision – machined to ensure accurate piston movement and proper sealing.

Pistons: The pistons are usually made of hardened steel and are carefully designed to fit snugly within the cylinders. Their dimensions and surface finish are crucial for minimizing internal leakage and maximizing pumping efficiency.

Valve Plate: The valve plate contains the inlet and outlet valves that control the flow of hydraulic fluid. It is made of a durable material and is designed to ensure precise and reliable valve operation, allowing for efficient fluid transfer.

3.2 Système d'étanchéité

The pump is equipped with a high – quality sealing system to prevent hydraulic fluid leakage. The seals are made of special elastomeric materials that are resistant to the hydraulic fluid used and can withstand the high – environnement de pression. The seals are located at various critical points such as around the pistons and at the pump housing joints.

Logo de machines Tonkee

Logo de machines Tonkee