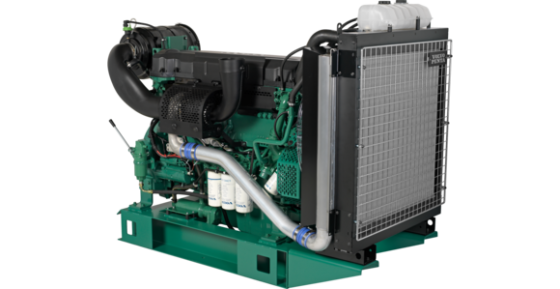

The specific pump used in these models is the VOE 11003810, which is a genuine Volvo part designed to meet the manufacturer’s high-quality standards.

The rebuild process for this pump follows a set of specifications provided by Partsdic®, a trusted supplier of Volvo construction equipment parts.

The rebuild of the VOE 11003810 pump begins with a thorough inspection to identify any signs of wear, damage, or failure. This includes assessing the pump housing, bearings, seals, ピストン, and other internal components. If any parts are found to be damaged or excessively worn, they are carefully removed for replacement.

The pump housing is cleaned and inspected for cracks or other defects. If necessary, it may undergo repairs or be replaced entirely. The bearings, which enable smooth rotation of the pump shaft, are inspected for wear and replaced if needed. Seals, which prevent fluid leakage, are examined, and any compromised seals are replaced to ensure proper hydraulic performance.

The pistons, which are responsible for pressurizing the hydraulic fluid, are inspected for wear, scoring, or other damage. If required, they are replaced with new ones that meet the original specifications. The cylinder block, which houses the pistons, is examined for signs of wear or damage and refurbished as necessary.

Other components, such as the valve plates, control discs, and springs, are inspected and replaced if found to be defective.

These parts play a critical role in regulating fluid flow and pressure within the pump.

Once all necessary parts have been inspected, repaired, or replaced, the pump is reassembled following the manufacturer’s specifications. This involves careful alignment of components and proper torquing of fasteners to ensure reliable operation.

After the rebuild process, the pump undergoes rigorous testing to verify its performance and functionality. This includes testing its ability to generate the required hydraulic pressure and ensuring that there are no leaks or abnormal vibrations during operation.

トンキーマシンのロゴ

トンキーマシンのロゴ