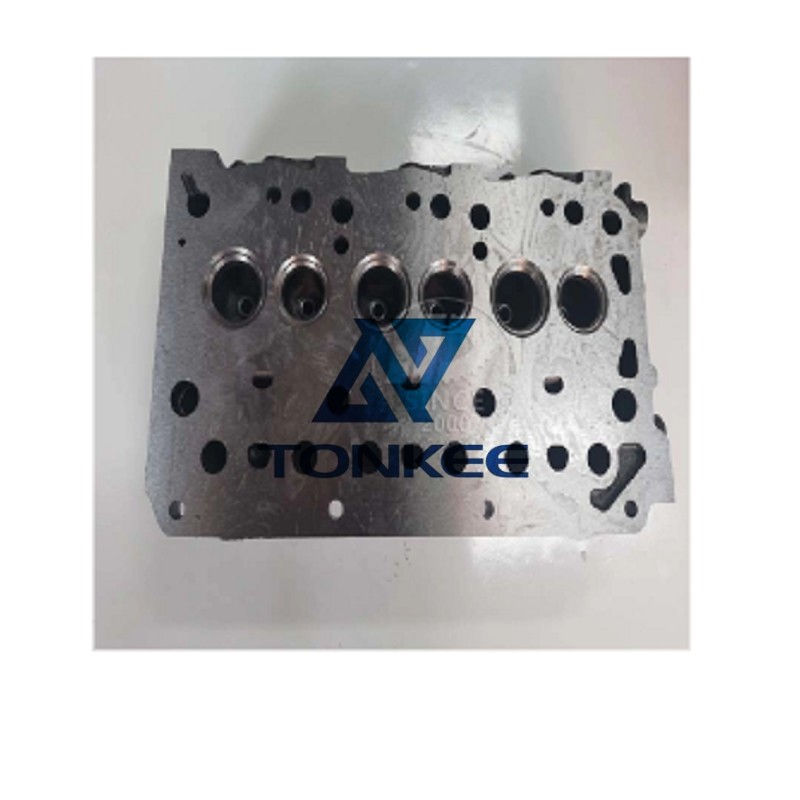

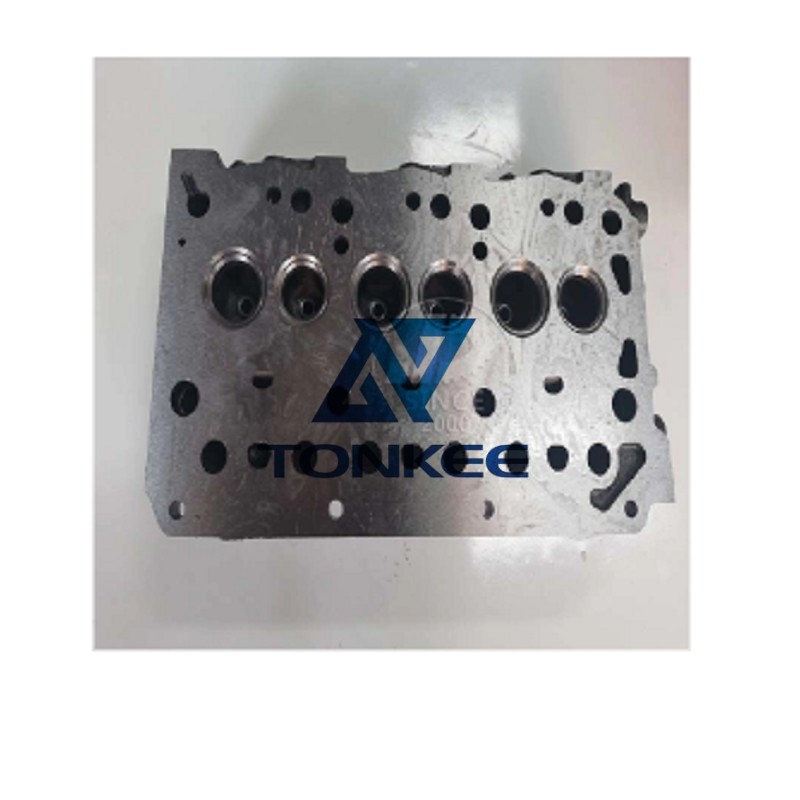

The cylinder head is designed to be compatible with Isuzu excavator engines of the 3LB1, 3LC1, and 3LD1 series. The part number 8971634010 is used to identify this specific cylinder head model, ensuring it fits precisely into the engine block of these particular engine types.

2. Material and Construction

Material: It is typically made of high – quality cast iron or an aluminum alloy. Cast iron provides excellent strength and heat – resistance, while aluminum alloy offers the advantages of lighter weight and better heat dissipation. The choice of material depends on the specific requirements of the engine's performance and design.

Structure: The cylinder head has a complex structure. It contains the combustion chambers where the fuel – air mixture is ignited. The shape and volume of the combustion chambers are carefully designed to optimize the combustion process for maximum power output and fuel efficiency. The cylinder head also houses the intake and exhaust ports, which are precisely machined to ensure smooth gas flow in and out of the cylinders. The ports' design affects the engine's breathing capacity and overall performance.

3. Valve Train Integration

The cylinder head is an integral part of the valve train system. It contains the valve seats and guides for the intake and exhaust valves. The valve seats are made of a hard – wearing material such as a special alloy or a hardened steel insert to withstand the high – temperature and high – pressure impacts of the valves during operation. The valve guides ensure the proper alignment and smooth movement of the valves, which are usually made of high – quality steel and have a specific stem diameter and length. The number of valves per cylinder can vary, but in modern excavator engines, it is common to have two intake and two exhaust valves per cylinder for better gas exchange.

4. Cooling and Lubrication Features

Cooling: The cylinder head has cooling passages integrated into its structure. These passages are designed to allow the circulation of engine coolant to dissipate the heat generated during the combustion process. The coolant passages are carefully routed to ensure efficient heat transfer from the critical areas of the cylinder head, such as around the combustion chambers and valve seats. The size and shape of the passages are optimized to provide sufficient cooling without sacrificing the structural integrity of the cylinder head.

Логотип Машины Тонки

Логотип Машины Тонки