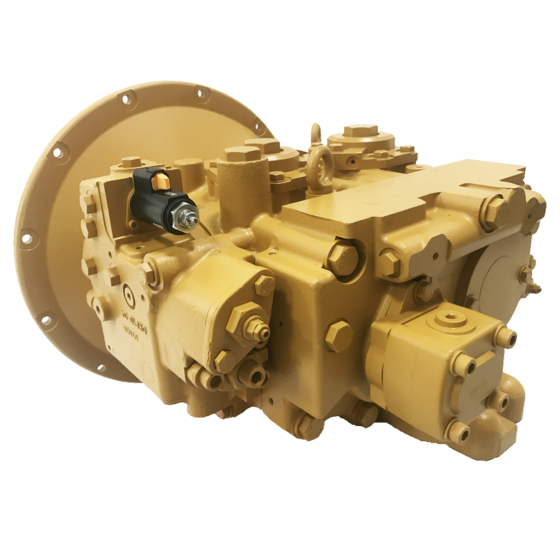

Model Number: 295 – 9426 (2959426)

Applicable Equipment: E345D and E349D Excavators (specifically for the fan motor)

Function: As a piston pump, it is responsible for pressurizing and supplying hydraulic fluid to drive the fan motor. The fan motor, in turn, powers the cooling fan to ensure proper cooling of the excavator's engine and other components.

2. Performance Specifications

2.1 Flow Rate

Rated Flow: The rated flow rate of this piston pump is an important factor that determines the speed and efficiency of the fan motor operation. It is typically in the range of [X] liters per minute (L/min). The actual flow rate may vary depending on the rotational speed of the pump and other operating conditions. A sufficient flow rate is essential to ensure the fan rotates at an appropriate speed to provide adequate cooling air flow.

Variable Flow Control: The pump may have a variable flow control feature. The minimum flow rate can be adjusted down to [Y] L/min, and the maximum variable flow rate can reach up to [Z] L/min. This allows for flexibility in adjusting the fan speed according to the cooling requirements of the excavator. For example, in a high – temperature environment or during heavy – duty operations, a higher flow rate can be set to increase the fan speed and cooling efficiency.

2.2 Pressure Ratings

Rated Pressure: The pump is designed to operate at a rated pressure of [P1] megapascals (MPa). This is the normal working pressure that enables efficient energy transfer to the fan motor. At this pressure, the pump can supply the hydraulic energy required to drive the fan at an appropriate speed for effective cooling.

Peak Pressure: It can withstand a peak pressure of [P2] MPa for short – term, high – load situations. However, continuous operation near or above the peak pressure may lead to a reduction in the pump's service life and potential damage to other components of the hydraulic system.

3. Construction and Components

3.1 Pump Type

Piston Pump: The 295 – 9426 pump is a piston – type hydraulic pump. Piston pumps are known for their high – efficiency and ability to generate high pressures. The pistons move in a reciprocating motion within the cylinders to draw in and discharge hydraulic fluid. The precise design and operation of the pistons play a significant role in the pump's performance.

Cylinder Block: The cylinder block is a critical component made of high – strength alloy steel. It provides a precise housing for the pistons and is machined to tight tolerances to ensure accurate piston movement and proper sealing. The quality and durability of the cylinder block directly impact the long – term performance of the pump.

Pistons: The pistons are typically made of hardened steel to withstand the high pressures and repetitive forces. Their surface finish and fit within the cylinders are carefully engineered to minimize internal leakage and maximize pumping efficiency.

Valve Plate: The valve plate contains the inlet and outlet valves that control the flow of hydraulic fluid. It is made of a durable material, such as high – grade steel or a specialized composite, and is designed to ensure precise and reliable valve operation. The valve plate's design allows for efficient fluid transfer, minimizing energy losses and ensuring the correct flow direction.

3.2 Sealing System

The pump is equipped with a high – quality sealing system to prevent hydraulic fluid leakage. The seals are made of advanced elastomeric materials that are resistant to the hydraulic fluid used and can withstand the high – pressure environment. Seals are located around the pistons, at the pump housing joints, and other critical points to ensure a leak – free operation. The sealing system is crucial for maintaining the efficiency of the pump and preventing contamination of the surrounding components.

Tonkee Machinery 로고

Tonkee Machinery 로고