1. What type of hydraulic pump is the Sauer JRR/JRL/LRL/RRS/FRR/JRRS Series?

The Sauer JRR/JRL/LRL/RRS/FRR/JRRS Series are high-pressure variable-displacement axial piston pumps (also called hydraulic plunger pumps) designed for heavy-duty industrial and mobile hydraulic applications. They are engineered for high efficiency, robust performance, and reliability in extreme operating conditions, such as construction machinery, 광산 장비, and agricultural machinery.

2. What are the key differences between the JRR, JRL, LRL, RRS, FRR, and JRRS sub-series?

Sauer’s sub-series are differentiated by displacement range, pressure rating, control options, and application focus:

- JRR/JRL: Compact mid-displacement models (typically 10–50 cm³/rev) with medium-to-high pressure ratings (최대 35 MPA), optimized for mobile equipment (e.g., small excavators, skid-steer loaders) due to their lightweight design.

- LRL: Medium-to-large displacement sub-series (30–100 cm³/rev, e.g., LRL030), designed for heavy-duty industrial and mobile systems requiring stable flow output at high pressure (최대 40 MPA).

- RRS/FRR: High-pressure, high-power variants (displacement 40–150 cm³/rev) with enhanced structural rigidity, suitable for extreme-load scenarios (e.g., mining trucks, large hydraulic presses).

- JRRS: Combined or multi-section configurations (based on JRR core design), supporting dual-circuit output for complex hydraulic systems.

4. What are the core performance specifications of the LRL030 (e.g., LRL030DLS2020NNN3C3NFA6NPLBNNNNNN)?

- Maximum Working Pressure: Rated pressure 35 MPA (350 kgf/cm²); peak pressure (short-term) 40 MPA.

- 속도 범위: 최저한의 800 RPM (to avoid cavitation); rated 1500–2500 rpm; maximum 3000 RPM.

- Output Flow: Calculated by Flow (L/분) = Displacement (cm³/rev) × Speed (RPM) ÷ 1000. Example: At 2000 RPM, theoretical flow = 30 × 2000 ÷ 1000 = 60 L/분 (actual flow varies slightly by control mode and pressure).

- Volumetric Efficiency: ≥ 94% (under rated pressure/speed); total efficiency ≥ 88%.

- Control Modes: Typical options include pressure-compensated control, load-sensing control, and proportional servo control (varies by the “디” segment in the model).

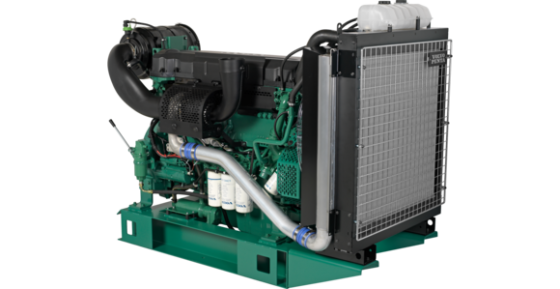

5. What applications are these Sauer plunger pumps suitable for?

They excel in heavy-duty, high-pressure hydraulic systems where reliability and efficiency are critical:

- Mobile machinery: Excavators, wheel loaders, mining trucks, agricultural tractors, and forestry equipment.

- Industrial machinery: Hydraulic presses, plastic injection molding machines, metal forming equipment, and marine winches.

- Specialized systems: Offshore oil drilling equipment, construction cranes, and waste management machinery.

6. What hydraulic fluids are compatible with these pumps?

- Recommended: Mineral-based hydraulic oils (ISOS VG 32, VG 46, or VG 68) with viscosity 15–46 cSt.

- Compatible alternatives: Synthetic hydraulic oils (e.g., PAO, ester-based) and biodegradable hydraulic oils (for eco-sensitive applications).

- Restriction: Avoid oils with impurities (particle size > 10 μm) or incompatible additives (refer to Sauer’s fluid compatibility guide).

7. What maintenance is required for Sauer JRR/JRL/LRL Series pumps?

- Oil Filtration: Use a ≥ 10 μm precision oil filter; replace filters every 2500 운영 시간.

- Fluid Check: Monitor oil level, temperature (10–60°C optimal), and contamination; replace hydraulic oil every 5000–8000 hours.

- Seal & Component Inspection: Check shaft seals, O-rings, and plunger packs quarterly for leaks; replace worn parts (e.g., 피스톤, cylinders) at 10,000–15,000 hours (varies by usage).

- Startup Precautions: Prime the pump with oil before startup (to prevent dry friction); avoid sudden pressure spikes beyond rated limits.

Tonkee Machinery 로고

Tonkee Machinery 로고